[最も人気のある!] yield point stress strain curve 330665-Shear yield strength stress strain curve

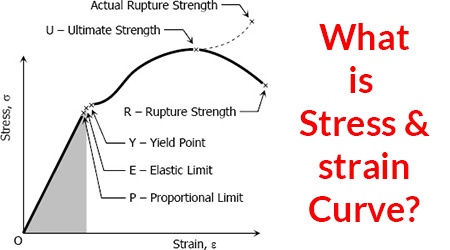

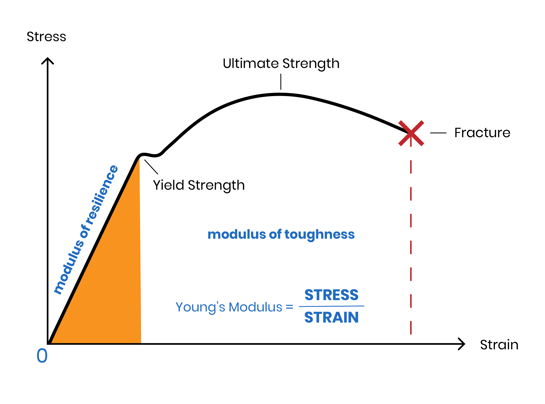

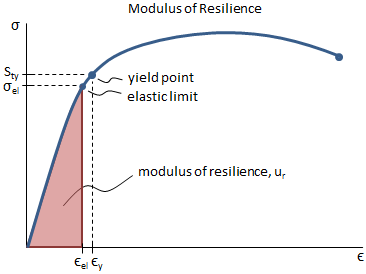

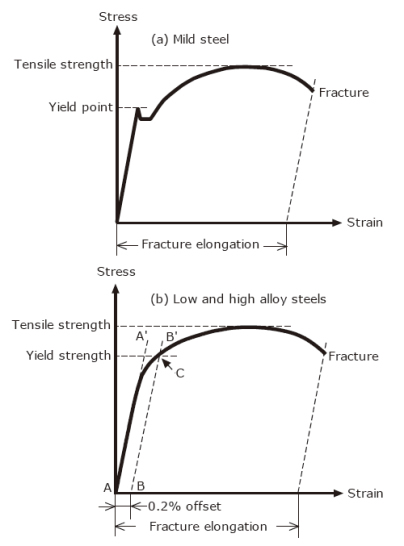

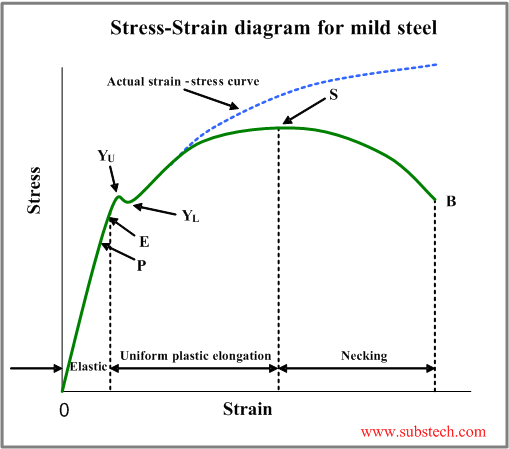

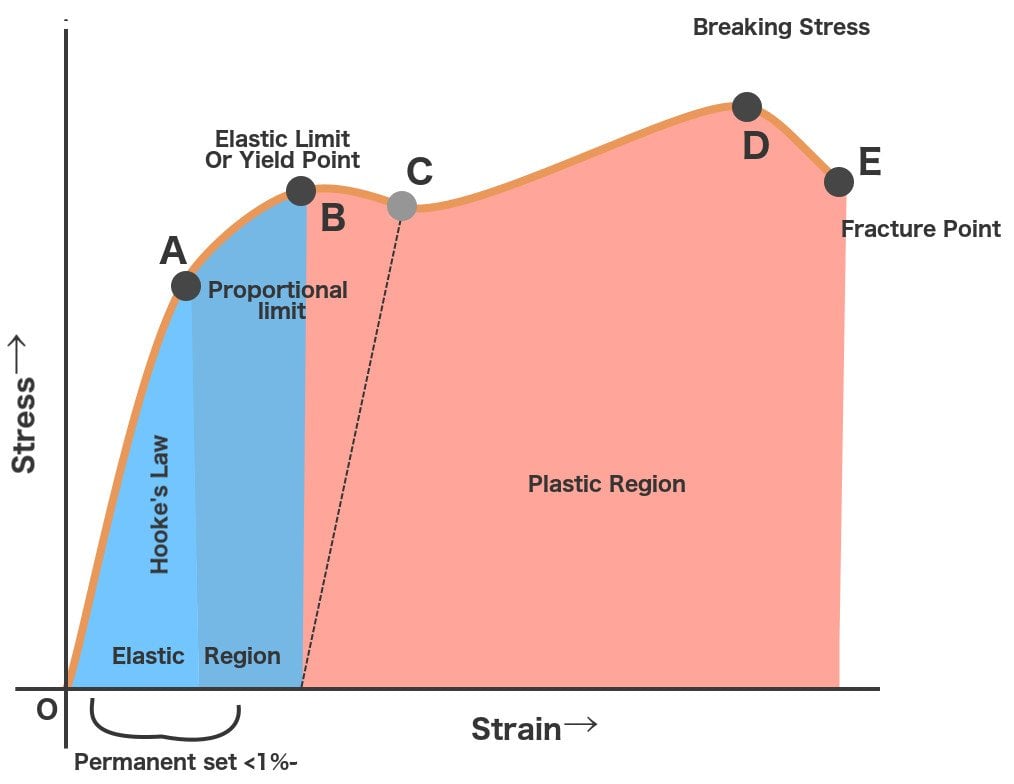

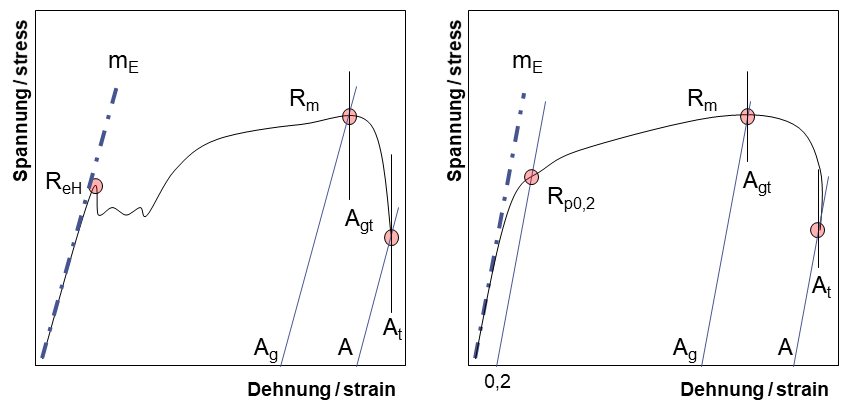

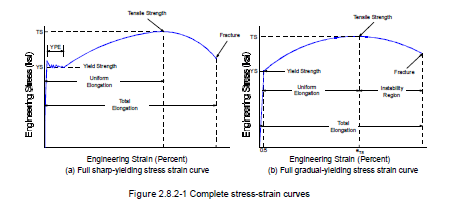

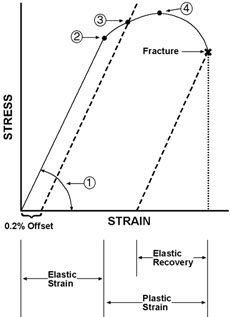

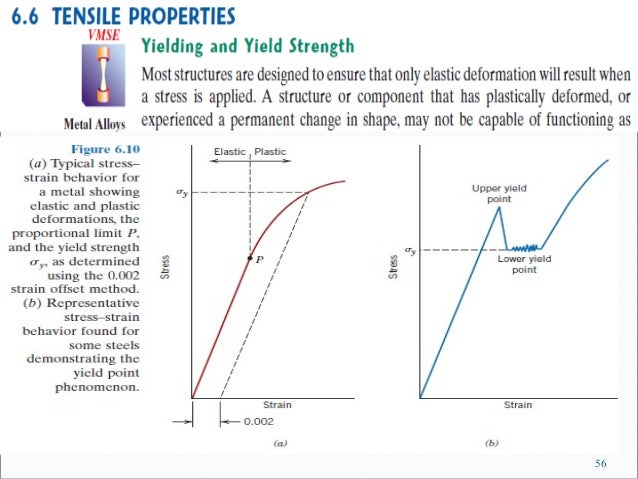

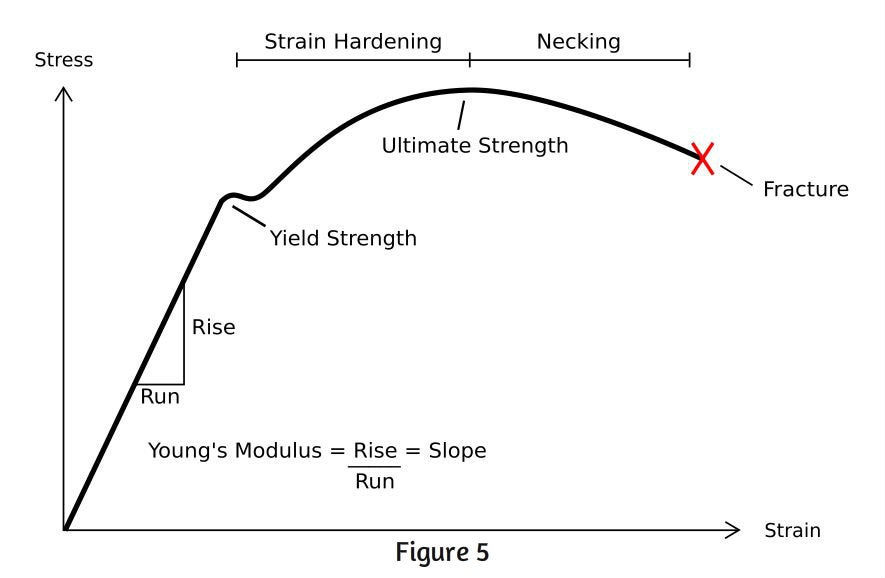

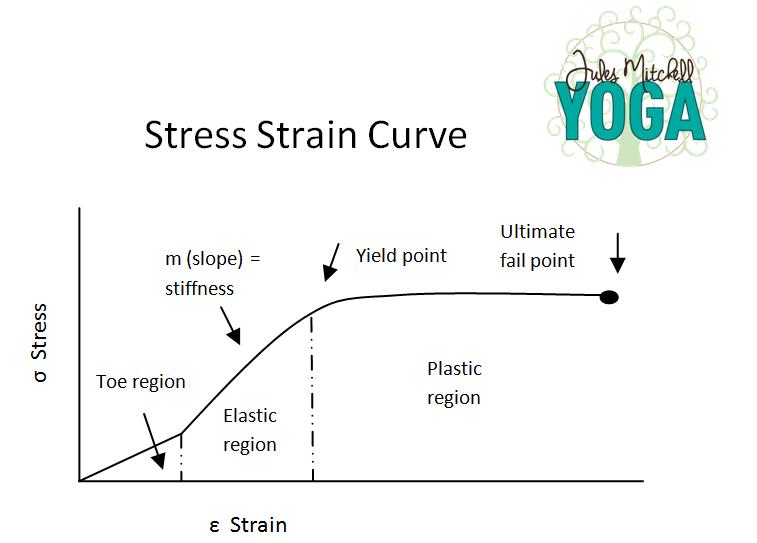

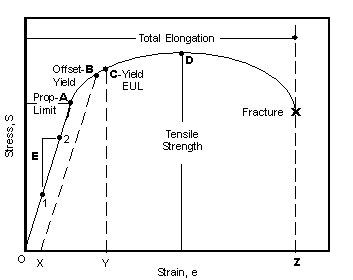

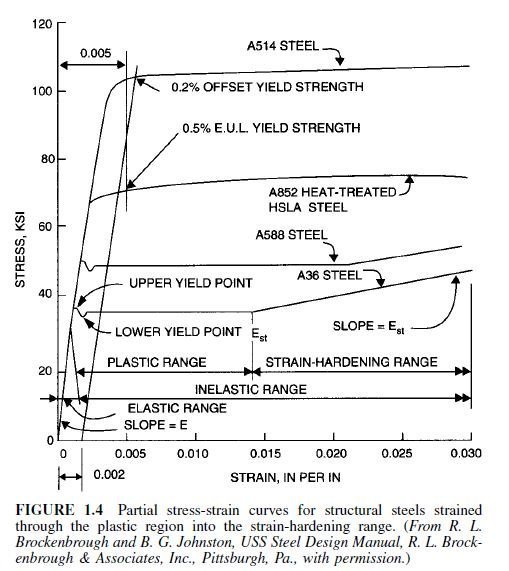

The stressstrain curve and a straight line with slope of E and beginning at 0002 (02%) on the strain axis The most satisfactory definition of yield strength for aluminum alloys and many other materials Note At this definition of yield, the plastic portion of the strain is 0002 and the elastic portion of the strain is σ y σ σ y E E 1 1 0 0002 ε εIn materials science and engineering, the yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning of plastic behavior Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed Once the yield point is passed, some fraction of the deformation will be permanent and nonreversible and is known as plastic deformation The yield strength or yield stress is a material propYield strength is a property often used to describe the stress at which the material begins to function in a plastic manner In the figure, the yield strength is represented by the point of intersection of the parallel line to the stressstrain curve

Getting Started With Abaqus Explicit Keywords Version V6 6

Shear yield strength stress strain curve

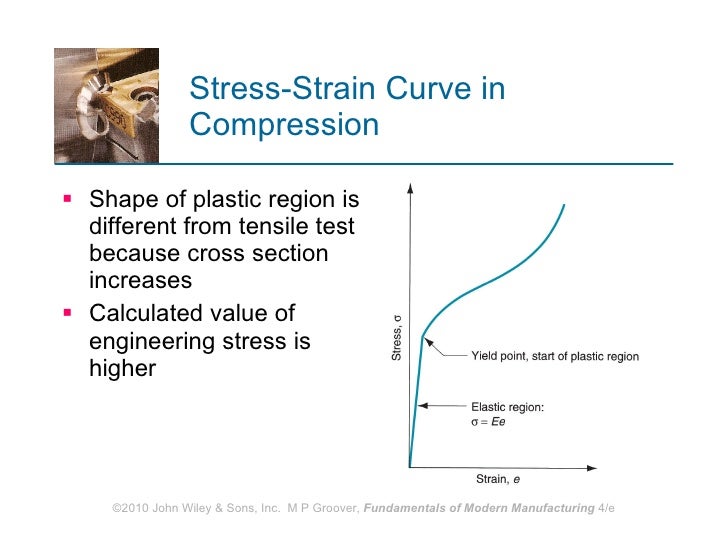

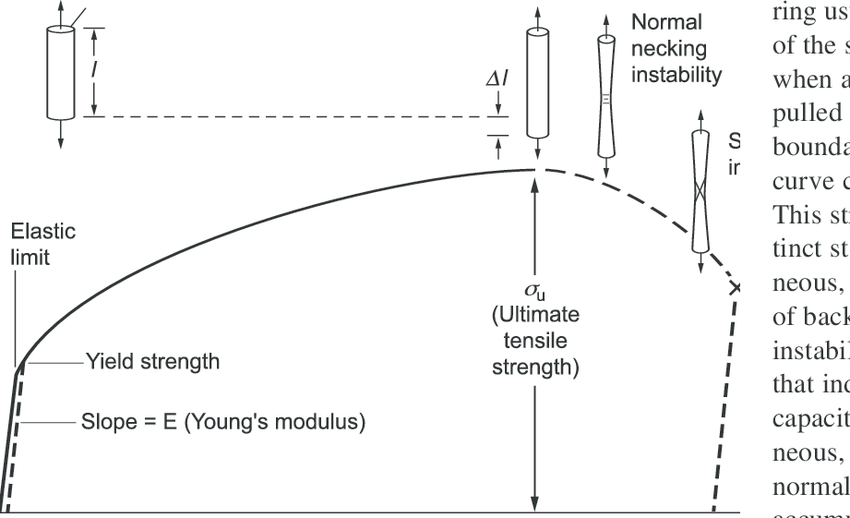

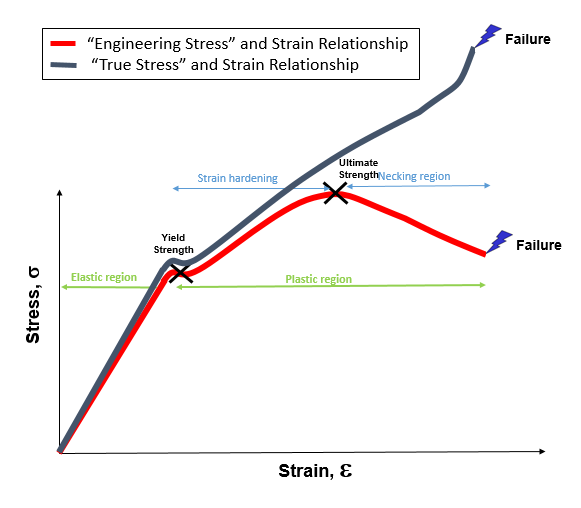

Shear yield strength stress strain curve-The true stressstrain curve is ideal for showing the actual strain (and strength) of the material Some materials scientists may be interested in fundamental properties of the material In this case, the true stressstrain curve is better This curve tells the actual state of stress in the material at any pointCan you please draw me a curve in graph for this stress and strain , and then find for me the value for the yield point , ultimate point (U) and the fracture (R) Show transcribed image text Expert Answer

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

The yield point of a material occurs when the material transitions from elastic behavior where removing the applied load will return the material to its original shape to plastic behavior, where deformation is permanent On a stress/strain curve, the elastic region is generally depicted as the portion of the curve with a constant slopeSome materials do not have a well defined yield point, so the yield point is defined as 02% plastic strain That could be point E on your curve Points Y1 and Y2 apply to some (not all) ductile materials, where the stress decreases immediately after yielding They are the upper and lower yield points So "the" yield point could be point E, point Y1, or somewhere between those two pointsThe formula for calculating strain is ε= (ll 0 )/l 0, where l 0 is starting or initial length (mm) l is stretched length (mm) For example, if a certain force changes a metal's length from 100 mm to 101 mm, the normal strain will be ()/100 or 001

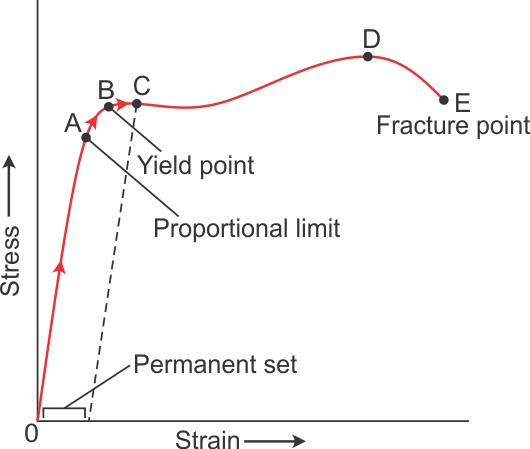

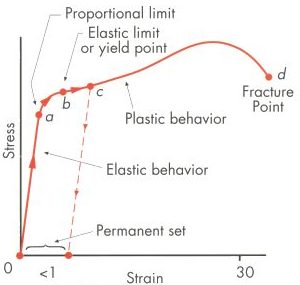

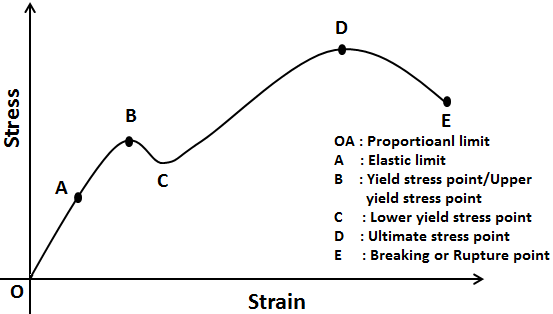

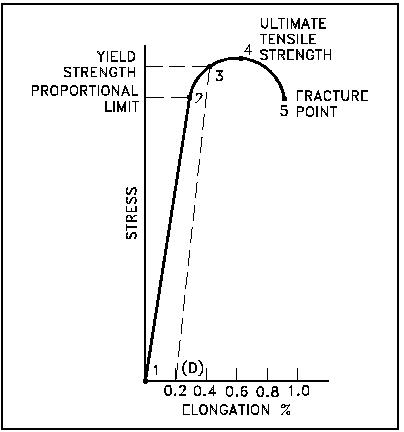

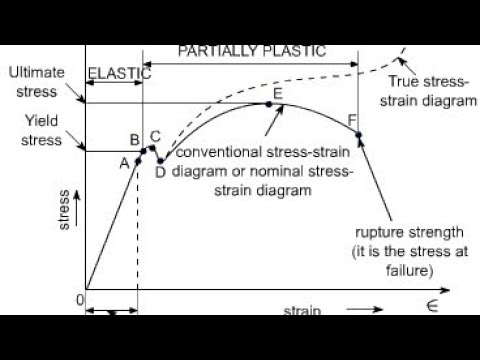

What is the point P shown in the stressstrain curve?Yield point in a stress strain diagram is defined as the point at which the material starts to deform plastically After the yield point is passed there is permanent deformation develops in the material and which is not reversible There are two yield points and it is upper yield point and lower yield pointHooke's Law and Stressstrain Curve The point B in the curve is the Yield Point or the elastic limit and the corresponding stress is the Yield Strength (S y) of the material Once the load is increased further, the stress starting exceeding the Yield Strength This means that the strain increases rapidly even for a small change in the stress

On the horizontal axis you have strain, and on the vertical axis you have stress The stressstrain curve will be directly proportional under proportional limit, ie, the curve will be linear starting from the origin Now, you just have to measuQuestion Please Draw Stressstrain Curve In Excel And Find Yield Strength,yield Strain, Stiffness,ultimate Strength,Resilience,Toughness,Brittleness,Ductility In (EL%) Original Length=006m Original Diameter= 15mm STRESS (N/mm2) STRAIN 0 0To determine the yield strength using this offset, the point is found on the strain axis (xaxis) of 0002, and then a line parallel to the stressstrain line is drawn This line will intersect the stressstrain line slightly after it begins to curve, and that intersection is defined as the yield strength with a 02% offset

The Differences Between Stiffness And Strength In Metal

Stress Strain Curve And Its Explanation Unbox Factory

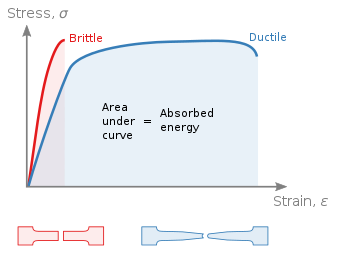

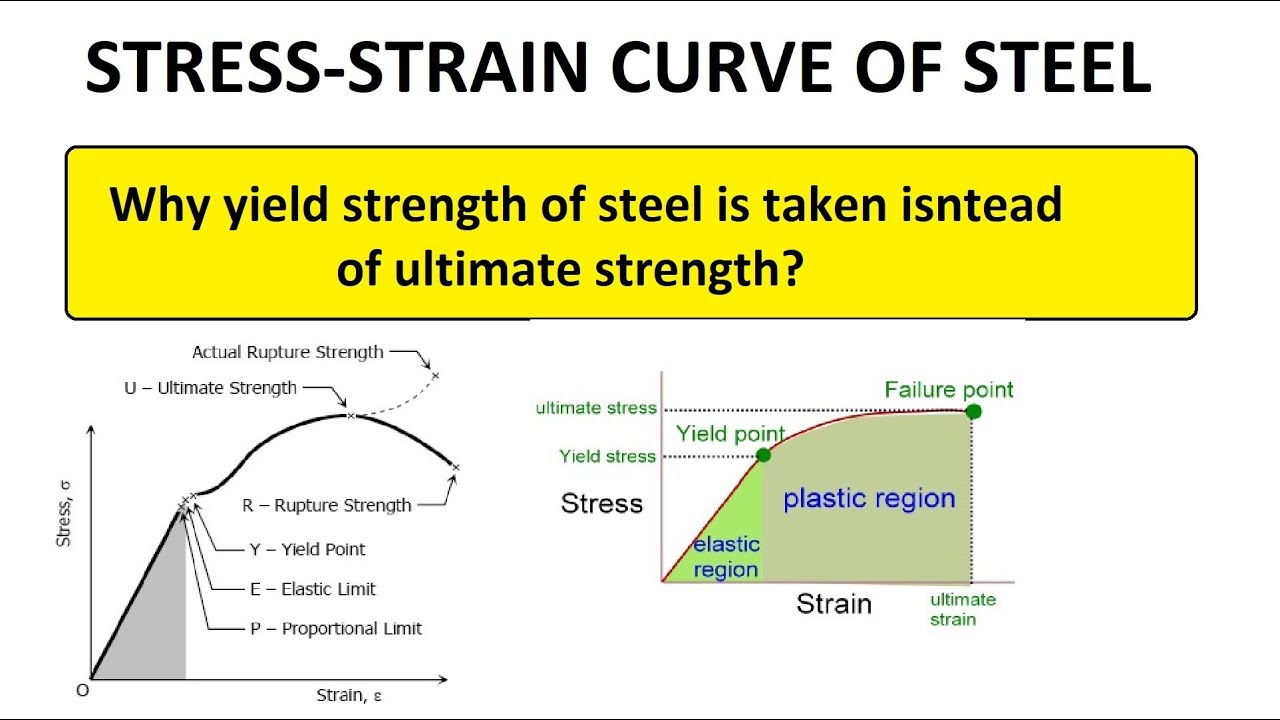

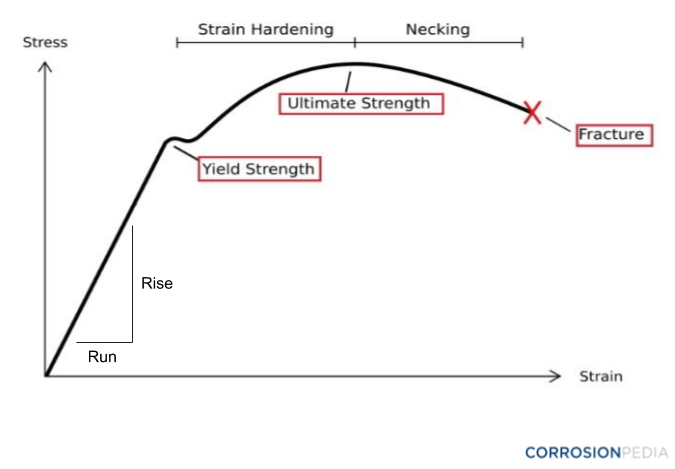

Point (BC) is the yield point on the graph and stress associated with this point is known as yield stress Ultimate Stress Point (D) Ultimate stress point is the maximum strength that material has to bear stress before breaking It can also be defined as the ultimate stress corresponding to the peak point on the stressstrain graphYield Point When we increase the load beyond the point C, the object starts to deform permanently or it will never get back its initial dimensions If we increases the load or stress continuously we reaches a point where the stress strain curve changes its slop and start to move in negative direction This point is shown by DThe following figure shows a typical stressstrain curve of a ductile material and a brittle material A ductile material is a material, where the strength is small, and the plastic region is great The material will bear more strain (deformation) before fracture

St Venant S Priciple Stress Strain Curve Me Subjects Concepts Simplified

Chapter 26 Biomechanics Musculoskeletal Key

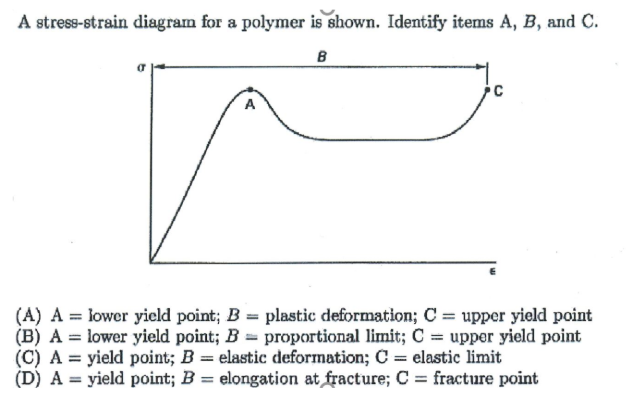

Stress Strain Behavior of Polymers Introduction The Stress/Strain behavior of solid polymers can be categorized into several classes of behavior 1) Brittle Fracture characterized by no yield point, a region of Hookean behavior at low strains and failure characterized by chonchoidal lines such as seen in inorganic glasses 2) Yield Behavior characterized by a maximum in the stress/strain curve followed by yielding deformation which is usually associated with crazing or shear banding andThe stressstrain curve is approximated using the RambergOsgood equation, which calculates theCan you please draw me a curve in graph for this stress and strain , and then find for me the value for the yield point , ultimate point (U) and the fracture (R) Show transcribed image text Expert Answer

Stress Strain Curve Wikipedia

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

It is found by drawing a line that crosses the X (strain) axis at 0002 and runs parallel to the stressstrain line (slope = E) The point where this line intersects the stressstrain curve is the offset yield point Finally, at point "D," where the curve begins to fall, the material's ultimate tensile strength has been reachedThe stressstrain curve and a straight line with slope of E and beginning at 0002 (02%) on the strain axis The most satisfactory definition of yield strength for aluminum alloys and many other materials Note At this definition of yield, the plastic portion of the strain is 0002 and the elastic portion of the strain is σ y σ σ y E E 1Can you please draw me a curve in graph for this stress and strain , and then find for me the value for the yield point , ultimate point (U) and the fracture (R) Show transcribed image text Expert Answer

The Stress Strain Curve Obtained By Loading A Sample Of Compact Bone In Download Scientific Diagram

Why Do We Use 0 2 Offset In Aluminum Stress Strain Curve Quora

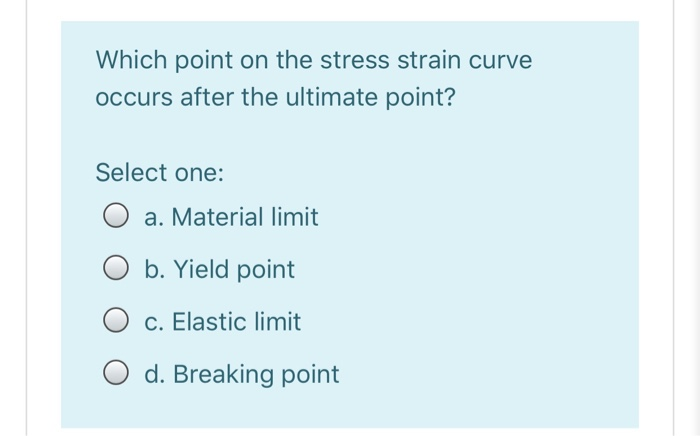

We will draw a graph of stress vs strain and explore all the different regions of it 0 energy points · Mechanical properties of solids · Stress, strain, and modulus of elasticity Stress vs strain curve Google Classroom Facebook Twitter Email Stress, strain, and modulus of elasticity Elastic and non elastic materialsA) Lower yield point b) Elastic limit c) Proportionality limit d) Breaking point Answer d Clarification The breaking point is the point where the material breaks The breaking point will be the last point on the stress strain curveTo find yield strength, the predetermined amount of permanent strain is set along the strain axis of the graph, to the right of the origin (zero) It is indicated in Figure 5 as Point (D) Yield Strength, Modulus of Elasticity, Ultimate Strength of Selected Materials A straight line is drawn through Point (D) at the same slope as the initial portion of the stressstrain curve The point of intersection of the new line and the stressstrain curve is projected to the stress axis

Elasto Plastic Materials Materials Simscale Documentation

Yield Strength Yield Point Stress Strain Curve

Strain Hardening Strain Hardening occurs when a material experiences plastic deformation During this the yield point is permanently moved to the right on the stress strain curve which leads to increasing the yield stress or hardening of the materialYield Strength Graph Each and every material possess characteristic stressstrain curve that allows us to determine what application they are best suited for Each materials curve possesses different points of transition ie from elasticity to plasticity and finally to breakageDuring this the yield point is permanently moved to the right on the stress strain curve which leads to increasing the yield stress or hardening of the material Necking At this point the cross sectional area starts shrinking within the necking region

Stress Strain Curve An Overview Sciencedirect Topics

Stress Versus Strain

In the stressstrain curve, yield strength is the point from where the stress deviates its proportionality to strain For a few materials, the yield strength in the stressstrain curve is distinct but for few others, it is not Hence, a concept of proof stress is used to denote the yield strength in the stress & strain curve for those materialsDuctile StressStrain Curve In this ductile material curve, you can see a point labeled yield strength, also known as yield point The dip in the curve at this point is an indication that theThe yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation begins

Yield Strength Strength Mechanics Of Materials Engineers Edge

What Is Young S Modulus

The stressstrain curve will follow the righthand elastic curve (straight line) portion of the diagram back up to point D, and will then continue deforming plastically Put another way, by unloading and then starting the test over you shift the origin of the plot to the right, to where the end of the unload line isIntial length 50mm ,intial area mm^2 ,calculate elongation ,stress ,stress and draw curve in excelStress Strain Curve – Yield Points 5Strain Hardening Region DE = Point D to Point E is Strain Hardening Region Strength of material is increased with the application of load in this region therefore more stress is required for deformation in this region

Strength At Break Tensile

Plot Stress Vs Strain Curve For A Metal On The Graph Depict I Yield Point Ii Fracture Point Iii Proportional Limit Iv Permanent Set Physics Topperlearning Com Ol7k1yrss

Ductile StressStrain Curve In this ductile material curve, you can see a point labeled yield strength, also known as yield point The dip in the curve at this point is an indication that theOn the horizontal axis you have strain, and on the vertical axis you have stress The stressstrain curve will be directly proportional under proportional limit, ie, the curve will be linear starting from the origin Now, you just have to measuThe yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation begins Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is removed

What Is Yield In Materials Yield Stress Yield Strength And Yield Point Materials Science Engineering

Mechanical Properties Of Materials Mechanicalc

Yield Strength (or yield stress, or yield strain) is the point between the elastic region and the plastic region This can sometimes be hard to determine, so it is conventionally defined as having 02% plastic deformationThe stress decreases until point C, which is known as the loweryield point, but as one can observe, the material continues to elongate Necking exhibits point 'D' of the stressstrain curve, whereas Fracture represents point 'E'RambergOsgood Equation The stressstrain curve is approximated using the RambergOsgood equation, which calculates the total strain (elastic and plastic) as a function of stress where σ is the value of stress, E is the elastic modulus of the material, S ty is the tensile yield strength of the material, and n is the strain hardening exponent of the material which can be calculated based on

Stress Strain Properties 2 Matlab Cody Matlab Central

Predicting Structural Instability Due To Plastic Hinge Collapse Mechanism Digital Engineering 24 7

Jalaj Kumar SirI think the 02% criteria is used when the yield point on the stressstrain curve is not exactly defined, which is generally in the case of brittle materials Ductile materialsThe following figure shows a typical stressstrain curve of a ductile material and a brittle material A ductile material is a material, where the strength is small, and the plastic region is great The material will bear more strain (deformation) before fractureThere are two yield points (i) upper yield point (ii) lower yield point (iv) Ultimate Stress Point It is a point that represents the maximum stress that a material can endure before failure Beyond this point, failure occurs (v) Fracture or Breaking Point It is the point in the stressstrain curve at which the failure of the material takes

Yield Strength Graph Dubai Khalifa

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

This point is known as the yield point A further increase in strain occurs without an increase in stress The stressstrain behavior of a polymer greatly depends on the temperature At very low temperature well below the glass transition temperature, brittle failure is observed as a break at low strain rate at the stress maximumA StressStrain Curve is all about how a particular material behaves under various levels of stresses until it breaks down or fractures The engineering stressstrain curve for a structural steel is shown above It consists of 5 parts that can be named as OA, AB, BC, CD and DEA StressStrain Curve is all about how a particular material behaves under various levels of stresses until it breaks down or fractures The engineering stressstrain curve for a structural steel is shown above It consists of 5 parts that can be named as OA, AB, BC, CD and DE

Yield Strength Engineer Educators Com

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Now, you just have to measure the value of 02% of strain and mark it on the strain (horizontal) axis Start drawing a line parallel to the stressstrain curve until it meets the curve at some point on the curve Draw a horizontal line from the meeting point until it meets the vertical (stress) axis Measure the value that will be the yield point stress corresponding to 02% of strainYP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength

Fracture Of Materials Ductile Fracture Yield Point Stress Strain Curve Youtube

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Yield Strength Definition Examples Stress Strain Graph Faqs

Stress Strain Curve Myrank

Q Tbn And9gcsydlmofdgt2pi Bjfg1pl7guunuh4ylpoytsjumqyubnqlzmba Usqp Cau

Yield Strength Strength Mechanics Of Materials Engineers Edge

Q Tbn And9gcqdhkmo7hherjjmwerev9j1zxqfwpmjetj5gvnkildcbtyau41x Usqp Cau

Material Properties Basic Science Orthobullets

Stress Vs Strain Curve For Mild Steel Basic Mech In

Stress Strain

Types Of Strength Bortec

Correlation Between Engineering Stress Strain And True Stress Strain Curve

1 1 6 Main Takeaways On Stress And Strain Tu Delft Ocw

Getting Started With Abaqus Explicit Keywords Version V6 6

What Is The Difference Between Upper Yield Point And Lower Yield Point Of A Stress Strain Curve For Mild Steel Quora

A Brief Guide On How To Calculate Area Under The Stress Strain Graph Science Struck

Engineering Stress Strain Curve

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Tensile Test And Stress Strain Diagram Substech

Stress Strain Curve Wikipedia

Chapter 26 Biomechanics Musculoskeletal Key

Yield Strength Defintion Examples And A Simplified Explanation

Solved A Stress Strain Diagram For A Polymer Is Shown Id Chegg Com

Stress Strain Curve Definition Examples Diagrams

Yield Point Yield Point Ratio Offset Yield Zwickroell

Stress Strain Diagram Cgkb

Yield Point Elongation Ype Pros And Cons

Stress Strain Behavior Of Polymers

Yield Point Instron

Ch 3 Mechanical Properties Of Materials Flashcards Quizlet

Yield Strength Definition Examples Stress Strain Graph Faqs

Hooke S Law And Stress Strain Curve Analysis Videos And Examples

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

Ch03

Steps To Analyzing A Material S Properties From Its Stress Strain Curve 9 Steps Instructables

Inhomogeneous Deformation

Materials The Problems With Single Point Data Plastics Technology

Indian Institute Of Technology

Stress Strain Curves For Unfilled Polymers Injection Mould Thin Wall Mould Container Mould Pallet Mould Bucket Mould Smc Mould Crate Mould

Ultimate Tensile Strength

Stress Strain Curve Strength Of Materials Smlease Design

Strength At Break Tensile

Stress Strain Curve For Mild Steel Explained Civilmint

Hindi Stress Strain Curve For Steel Yield Strength Vs Ultimate Strength Youtube

What Is Stress Strain Curve Mechanical Engineering Full Explanation

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

Why Does The Stress Strain Curve Decrease Engineering Stack Exchange

What Is Proof Stress Civildigital

Industrial Design Guide Yield Strength

Stress Strain Curve Definition Yield Point General Class Video Study Com

Tensile Stress Strain Curve The Tensile Test Is The Most Common Test Download Scientific Diagram

Stress Strain Curve Wikipedia

Yield Strength

Lec 2 Stress Strain Diagram Lec 2

Explanation Of Stress Strain Curve

Steps To Analyzing A Material S Properties From Its Stress Strain Curve 9 Steps Instructables

Solved Which Point On The Stress Strain Curve Occurs Afte Chegg Com

Cee 3710 Strength Versus Stiffness

Tissue Mechanics Connective Tissues Jules Mitchell Yoga

Astm E8 Measuring The Tensile Strength Of Metals

Motion Design 101 Stress Strain Curves Machine Design

How Tensile Strength Relates To 3d Printing Make Parts Fast

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Stress Strain Curve Diagram Basic Mechstudies

Yield Point Civil Engineering

The Stress Strain Curve Intro To Structural Engineering

Does Unloading Beyond Yield Point Also Affect Tensile Strength Engineering Stack Exchange

Stress And Strain Mechanical Properties Of Materials

Yield Point Definition Curve Elongation General Class Study Com

How Do You Identify The Elastic Limit And Yield Point On A Stress Strain Graph Physics Stack Exchange

Engineering Stress And Strain Curve Diagram

Engarc L Offset Yield Method

Stress Vs Strain Curve Yield Point Yield Strength Elastic Limit Neking Ultimate Tensile Youtube

Stress Strain Diagram Instron

Explain Stress Strain Diagram For A Wire Under Continuously Increasing Load Discuss

What Is A Proof Stress Definition From Corrosionpedia

Lecture Notes

What Is Yield In Materials Yield Stress Yield Strength And Yield Point Materials Science Engineering

Stress Strain Curve Full Explanation Mech4study

コメント

コメントを投稿